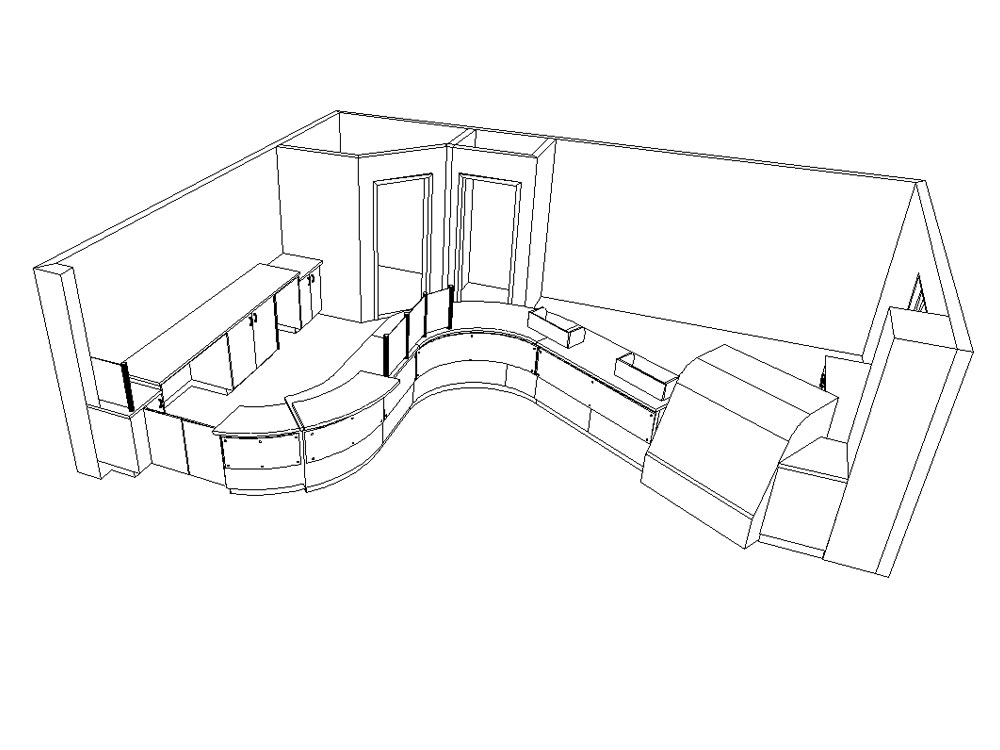

ProCabinet Solutions brings your ideas and designs to life through quality artisanship and custom craftsmanship, all the while paying close attention to the details and exceeding the WI (Woodwork Institute) and AWI (Architectural Woodwork Institute) industry standards. The building of a professional grade cabinet involves the utilizing of the best grades of raw materials coupled with the highest quality hardware and accessories in fabrication efforts. Three dimensional cabinet modeling software is employed to ensure quality of design. This allows for the design to be precisely engineered and then passed straight through to an automated manufacturing system. We have been producing professional grade Cabinetry & Millwork to the marketplace for well over 25 years.

The Contractors Choice

Attention to detail, comprehensive submittals, detailed three dimensional drawings, application of the latest in design software, highly skilled personnel at every level and countless years of experience in the industry makes ProCabinet Solutions the contractors choice.

Quality in the Details

Quality and attention to detail are paramount to a successful project installation. ProCab Solutions has consistently delivered a well manufactured finished product to the Commercial and Retail markets. The same level of drawings and submittals, exacting incorporation of specialty appliances, tight coordination and cooperation with other subs and access to our professional sources is now available direct to you!

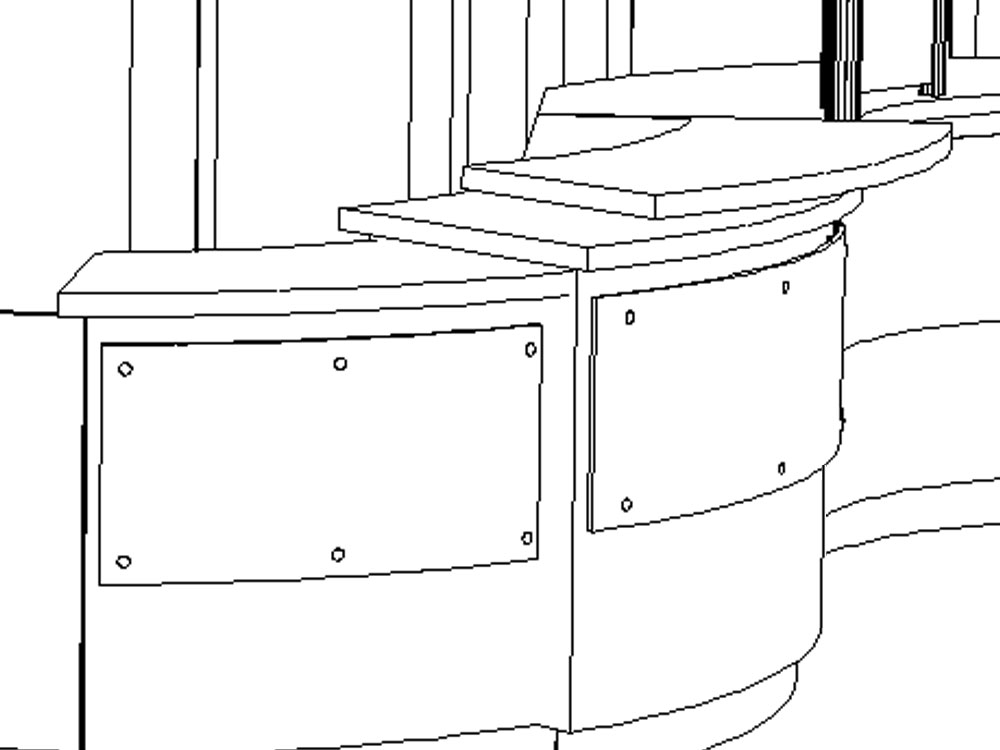

Residential, Professional, Business & Retail Environments require a special and extensive understanding of how different types of businesses operate. ProCabinet Solutions not only supplies an extremely durable product perfectly suited for the, high traffic, heavy use, work or retail environment but can also help insure that your home kitchen, reception counter, workstations, break rooms and food service areas are beautifully integrated with your personal interior design style.

Having been involved in LEED projects and maintaining a strict compliance with local, state and federal requirements, like the Americans with Disabilities Act and HIPAA, ProCabinet Solutions will partner with you to fulfill your vision of design.

State of the Art Manufacturing

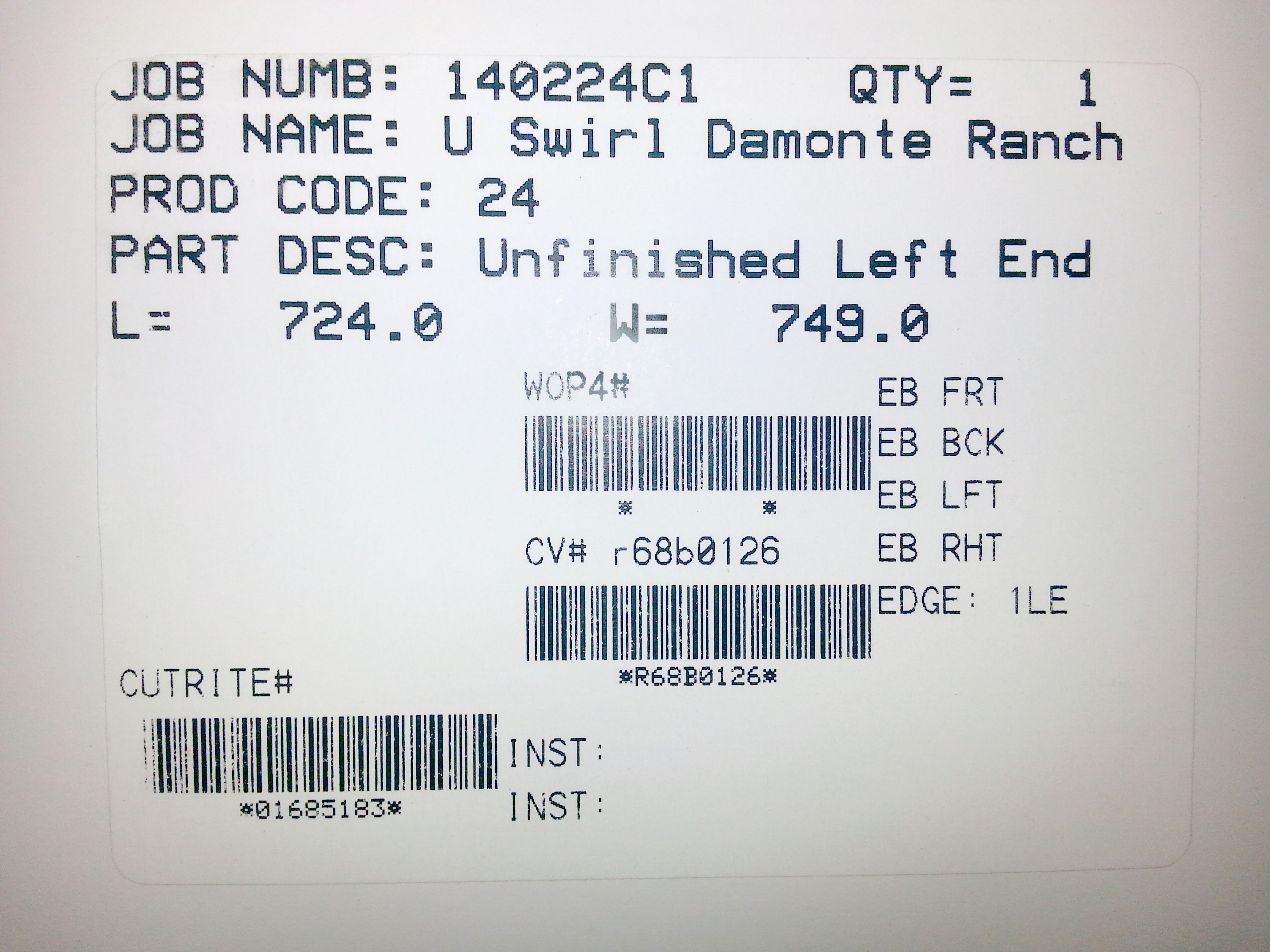

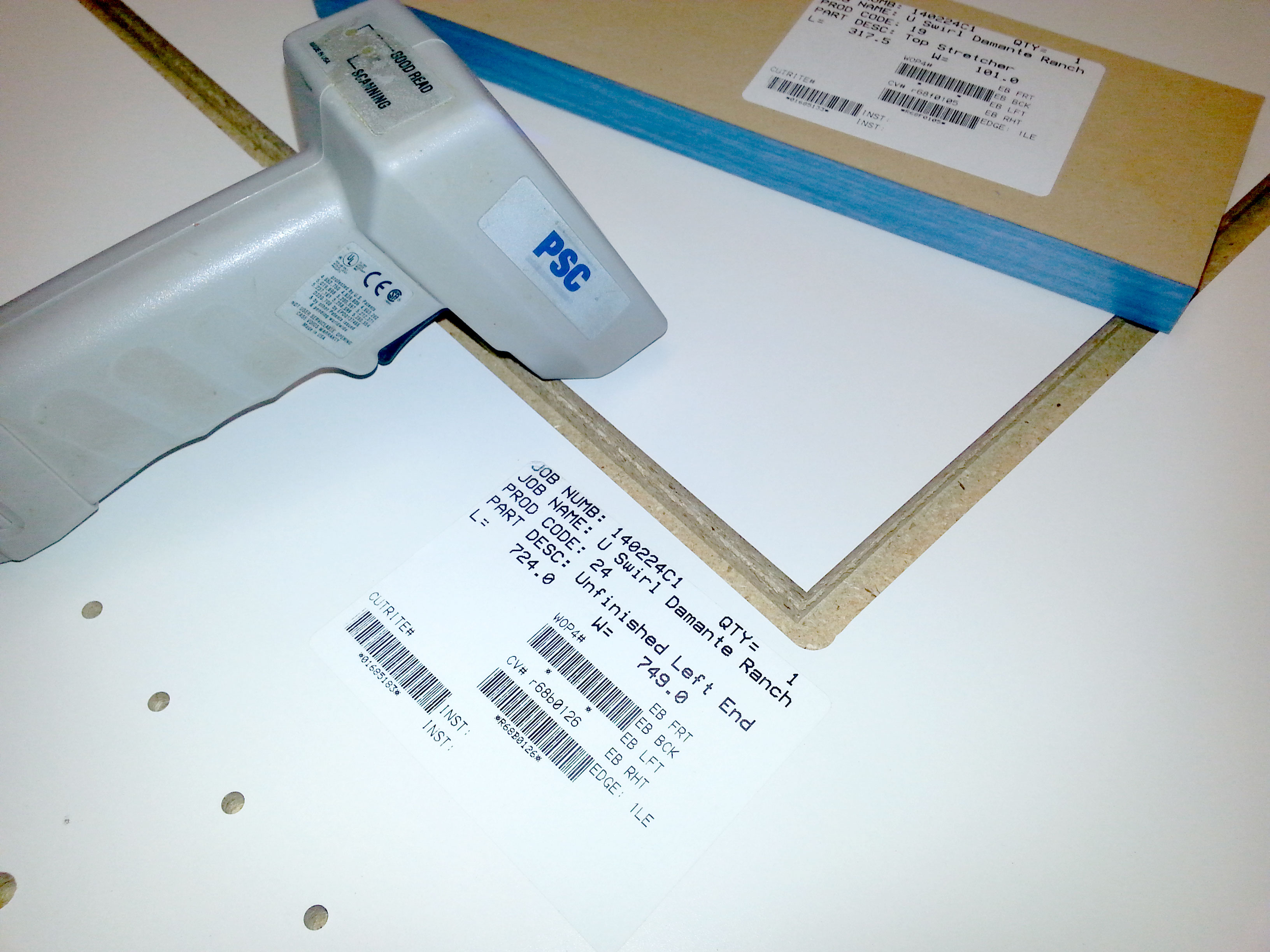

Every project ProCabinet Solutions builds is first completely engineered and 3D modeled using the latest in cabinet production software. Every sheet of material, accessory and individual piece of hardware is counted, optimized and considered prior to manufacturing. Every part we manufacture is labeled at our computerized beam saw with the information about the specific manufacturing needs of each part. Labels are printed with a bar code that is used to call up the specific program for precision machining. The label ties the part directly back to the individual cabinet it belongs to. Speed of installation is greatly aided in that every cabinet’s label ties its location directly back to the room and elevation it belongs to.